-

-

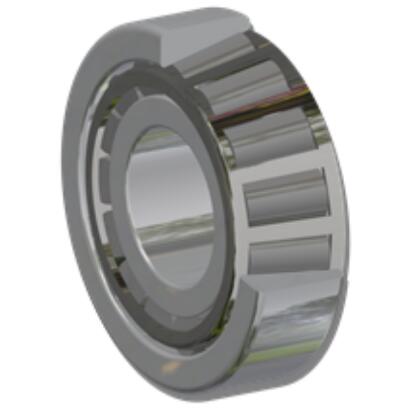

Product name: Single-row tapered roller bearing

-

-

Price: ASK

-

-

Post date: 2023-09-20

-

-

Stock Quantity:

-

Description:

Product features

The bearing is a separate type bearing, and the inner drawing assembly can be installed separately

from the outer ring of the national cone;

The outer ring and the inner assembly can be used in general mutual operation;

Double-row and four-row bearing have been determined according to user needs when the product

leaves the factory, and do not need users to adjust;

Especially suitable for bearing compound (radial and axial) load. The greater the contact angle, the

greater the applicability of bearing axial load.

Main areas

Automobile, rolling mill, mining, metallurgy, plastic machinery and other industries.

Tapered roller bearing belongs to the separation type of bearing, inside and outside of bearing have a conical mounting: its inner diagram and a group of dimensional roller by the graphic cage package formed an inner diagram tear, the outer diagram can be separated from the inner diagram components, this type of bearing according to the number of columns of the installed roller is divided into single-row, double-row and four-row tapered roller bearings and other different structural types. Tapered roller bearing is 100% interchangeable between the outer ring and the inner assembly.

The capacity of axial load depends on the contact angle, that is, the angle of the outer ring raceway, the larger the angle line, the greater the axial load capacity, when the bearing supports the radial load, an axial component will be generated, so when another bearing can bear the opposite direction axial force to balance. Compared with angular contact ball bearing, the bearing capacity increases and the limiting speed decreases. HBR tapered roller bearing adopts the optimized three -convex design method, and finds the most suitable flange requirements through the simulation of working conditions, so as to reduce the deep contact force and increase the fatigue life of the bearing. HBR automotive tapered roller bearing adopts non-standard design and processing method, which can provide the best solution for car users. For many years, HBR has been stable in large and medium-sized automobile and parking enterprises at home and abroad.

Product features

The bearing is a separate type bearing, and the inner drawing assembly can be installed separately

from the outer ring of the national cone;

The outer ring and the inner assembly can be used in general mutual operation;

Double-row and four-row bearing have been determined according to user needs when the product

leaves the factory, and do not need users to adjust;

Especially suitable for bearing compound (radial and axial) load. The greater the contact angle, the

greater the applicability of bearing axial load.

Main areas

Automobile, rolling mill, mining, metallurgy, plastic machinery and other industries.

The capacity of axial load depends on the contact angle, that is, the angle of the outer ring raceway, the larger the angle line, the greater the axial load capacity, when the bearing supports the radial load, an axial component will be generated, so when another bearing can bear the opposite direction axial force to balance. Compared with angular contact ball bearing, the bearing capacity increases and the limiting speed decreases. HBR tapered roller bearing adopts the optimized three -convex design method, and finds the most suitable flange requirements through the simulation of working conditions, so as to reduce the deep contact force and increase the fatigue life of the bearing. HBR automotive tapered roller bearing adopts non-standard design and processing method, which can provide the best solution for car users. For many years, HBR has been stable in large and medium-sized automobile and parking enterprises at home and abroad.